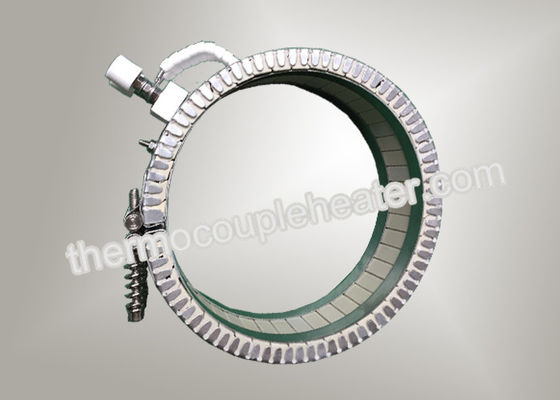

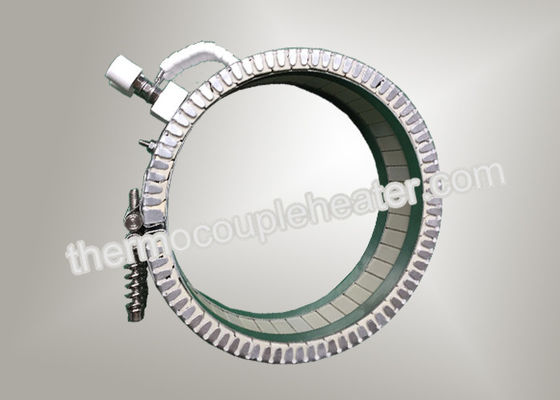

Band ceramic industrial nozzle heaters for Plastic Extruder injection molding Machine

Description:

1) Ceramic Insulated Band Heaters conserve energy by using a 1/4" thick ceramic fiber insulating blanket reducing power consumption by 25 to 30 percent. Because of the low thermal conductivity of the ceramic fiber insulation the external surface temperature of the Ceramic Insulated Band Heater is approximately 400ºF while running the inside surface temperature at 1200ºF. The most common applications include plastic injection molding machines extruders and blow molding equipment.

2) Nozzle type Ceramic Insulated Band Heaters apply glaze with good quality, ceramic with good heat and shock property are sintered once by nichrome wire.

3) Heat losing of Ceramic Insulated Band Heaters in the non-radiation surface is small.

4) Ceramic Insulated Band Heater has energy efficiency and environmental protection benefits.

5) The radiated element of Ceramic Insulated Band Heater is heated after electrifying to rating power and immerged into cold water after interruption of power supply for forty times without damage.

Specification:

1) GME's electric heater bands can replace the traditional heater bands for injection molding machine.

2) Adopting aluminum alloy liner, thermal efficiency is more than twice the conventional heater band

3) Heating up fast, effective insulation, energy-saving, small impact on environment temperature.

4) Voltage 110-380V, AC and DC , 50 / 60HZ.

Please specify the following when ordering:

1. The inner diameter (mm) and length (mm) of heaters

2. Thickness of heaters

3. Voltage and power rater

4. Operating temperature

5. Order quantity

Your detailed dimension will be highly appreciated.

| band heater |

ceramic band heater |

| Sheath |

stainless steel |

| heating wire |

Nickel Chrome wire |

| insulation |

ceramic |

| termination |

ceramic terminal/flange/lead/terminal box and customized |

| shape |

customized available |

| Industrial Heater |

Ceramic Band Heater |

| Resistance Wire |

NiCr 80/20 |

| Sheath |

304 stainless steel |

| Insulation |

Ceramic |

| Heater Voltage |

120V 220V 230V 240V 480V standard

(other voltages available on request)

|

| Max temperature |

550 degree celsius |

| Dimension |

Customized |

| Save energy |

30% |

| Min diameter |

60mm |

Application:

1) Widely used in Injection Moulding about Ceramic Insulated Band Heaters

2) Film extruders about Ceramic Insulated Band Heaters

3) Blow Moulding about Ceramic Insulated Band Heaters

4) All Plastic & Rubber Processing Machinery about Ceramic Insulated Band Heaters

Advantage:

1) Cheap, robust and easy to install, highly compacted they reach a surface watt density of up to 2-3w/cm2 and withstand highest stress

2) Apart from our board standad range we also develop and manufacture heaters according to your speacial demands

3) When ordering please specify diameter+lenght of the heater+wattage+voltage or drawing of special type configuration.If not,please tell us your requirement,we will design if for you

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!