Thermal Insulation Covers Energy-Saving Heat Protection for Band Heaters

1. Introduction

Removable thermal insulation covers are used to cover heaters, processing pipes, valves, flanges, instrumentation panels, and other components. Unlike permanent hard insulation, soft insulation covers have the advantage of being removable and reusable, making them the insulation of choice for components that need to be accessed from time to time for maintenance and inspection.

While removable thermal insulation covers are typically one of the last items to be installed before a facility goes into production, they are a critical component when it comes to site safety and system stability.

Heaters, pipes, valves, flanges, and other components left uncovered can result in:

Unnecessary process adjustment due to heat loss.

False readings or alarms being sent to the control room.

Equipment failures due to operation outside of normal temperature ranges.

Degradation of product quality due to improper process temperatures.

Process piping and equipment left without a properly designed thermal insulation cover can freeze and fail to properly operate.

2. Benefits

Heat retention and freeze protection.

Personnel protection against burns from hot components.

Energy savings from reduced heat loss to surrounding environment.

Sound attenuation.

Insulation is easily removed and replaced to allow for maintenance and inspection.

3. Construction

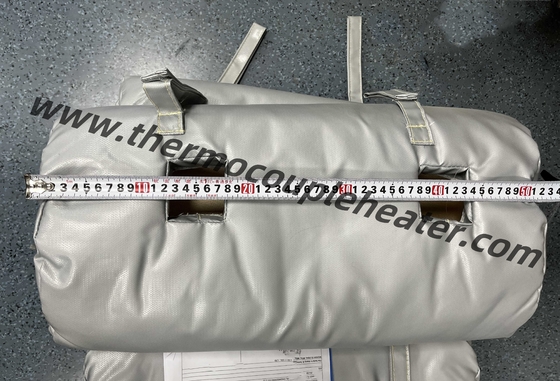

Removable insulation covers are typically constructed in 3 layers. The photo below illustrate the construction used in a standard removable insulation cover. Note that for different demanding and unique applications, GME offers a wide range of materials and construction.

Fastening methods include straps, lacing wire, cords, buckles, and Velcro.

Removable insulation covers feature high temperature sewn construction and incorporate flaps, closures, and cutouts to provide easy access to ports and controls.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!