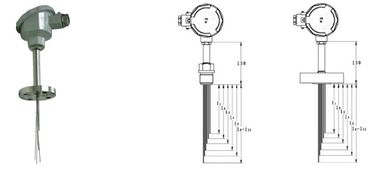

Assemblied Multipoint Thermocouple Rtd Temperature Sensor For Industry

Application:

Applicable for the measuing of temperature at different points onsite, widely used in large chemical fertilizer synthesis tower or storage tanks etc.

Parameters:

TYPE K (NICR-NI EX),

TEMPERATURE RANGE: -200C To +1000C,

SHEATH MATERIAL: SS, INCONEL,

CONNECTION FLANGE 1-1/2 IN,

INSERT DIAMETER: customized, OVERALL LENGTH: customized,

FFT: RF 150 LBS, 4-STAGE MULTIPOINT;

CONNECTION BOX: customized with terminals,

STAINLESS STEEL, 4 CABLE GLANDS, M20 X 1.5 (BRASS),

EXTENSION TUBE LENGTH (K): customized,

INSERTION LENGTHS : customized,

ERROR LIMIT: CLASS 1.

Features:

1. The sensor can be mounted into a thermowell or directly into a process with the use of a fixed, spring loaded or compression process fitting.

2. The assembly can be supplied with or without a transmitter. Transmitters convert the millivolt input from the thermocouple to a linear analogue or digital output (commonly 4-20 mA). This signal reduces potential inaccuracies in the circuit and negates the requirement for thermocouple extension wire.

3. The assembly has electrical approvals for explosion proof hazardous locations, intrinsic safety, ingress protection and general purpose areas.

4. The thermocouple sensors available for this assembly are provided with a variety of sheath materials including stainless steels, corrosion resistant and high temperature oxidation resistant alloys.

Thermocouple diameters range from 0.125 inch to 0.250 inch and 2 mm to 8 mm. Standard diameters are 0.125 inch & 0.250 inch also 3 mm & 6 mm.

5. Thermocouple temperature ranges are dependent on the sheath & conductor diameter, element calibration, and sheath material.

6. A variety of neck extensions are possible. They provide a fixture from the enclosure (connection head) to the process or thermowell. The standard neck extensions are the nipple-union-nipple or the male threaded neck tube. These extensions allow for directional rotation of the head for field wiring as well as a positive quick disconnection of the assembly from the process or thermowell.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!