Wuhan Global Metal Engineering Co., Ltd

The pioneer manufacturer of heaters & sensors

| Place of Origin: | China |

| Brand Name: | GME |

| Certification: | CE & ISO |

| Model Number: | 4.2 X 2.2mm |

| Minimum Order Quantity: | 1 pieces |

|---|---|

| Price: | negotiation |

| Packaging Details: | Export Carton Box |

| Delivery Time: | 7-15 working days |

| Payment Terms: | L/C, D/P, T/T, Western Union, Paypal |

| Supply Ability: | 20,000pcs per month |

| Product Name: | Hot Runner Coil Heater | Thermocouple: | Type J, K |

|---|---|---|---|

| Application: | Injection Mold Hot Runner | Material: | Stainless Steel 304, 316 |

| Moisture Proof: | IP 65 | Insulated Material: | Comressed MgO |

| Warranty: | 1 Year | Lead Wire Length: | 1000 Mm Or Customized |

| High Light: | 750℃ Thermocouple Inbuilt Coil Heaters,ISO 220V Coil Heaters,240V Hot Runner Coil Heater |

||

Cable / Coil Heaters With Inbuilt Thermocouple And SS Braided Protection Sleeve

1. Coil Heater Brief Introduction

The coil/cable heater can be formed into a variety of shapes. Cable heaters are small diameter,high-performance units, fully annealed and readily bent to a multitude of configurations.The cable heater can be formed into a compact, coiled nozzle heater supplying a full 360 degrees

of heat with optional distributed wattage. A straight cable heater can snake through an equipment application. Flat spiral configurations can be used in high-tech manufacturing while a star wound cable can be used for air and gas heating. Different applications require different construction methods, including one, two or four resistance wires; parallel coil or straight wire; drawn or swaged sheaths; with or without internal thermocouples; leads exiting from one or both ends, and round, rectangular or square cable cross sectionals.

2. Feature

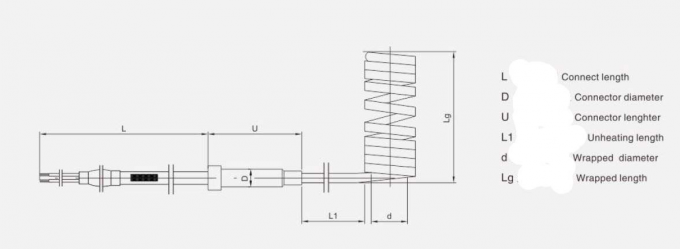

3. Coil Heater Parameter.

|

Spring coil heater (H series) |

3.0x3.0 |

Φ3.0 |

Φ4.0 |

Φ5.0 |

3.5x3.5 |

5.0x5.0 |

|

Voltage |

220V,230V,240V |

|||||

|

Power tolerance 115W-200W |

+/-10% |

|||||

|

Power tolerance 201W-2000W |

+5%-10% |

|||||

|

Out jacket length |

30mm~280mm |

|||||

|

Diameter of the inner sleeve/wrapped diameter |

10mm~42mm |

|||||

|

Unheating length |

45mm |

|||||

|

Max power density |

9W/cm² |

|||||

|

Heating Length tolerance |

+/-0.05mm |

|||||

|

Unheating length tolerance |

+/-2.5% |

|||||

|

Tolerance ID d ≤20mm |

Without inner sleeve:-0.15mm |

|||||

|

Tolerance ID d 20mm~30mm |

Without inner sleeve:-0.20mm |

|||||

|

Tolerance ID d ≥30mm |

Without inner sleeve:-0.25mm |

|||||

|

Tolerance cross section |

+/-0.15mm |

+/-0.20mm |

||||

|

Thermocouple |

K,J,E |

None |

||||

|

Material |

304,321,316 |

|||||

|

Maximum working temperature |

750℃ |

|||||

|

Die electrical strength |

800V |

1000V |

||||

4.Spring Coil Heater Application

This Heating Coil is widely applied for hot runner system, plastic industry, packaging machinery, medical

equipment, casting process,other electric heating industry, etc..