Wuhan Global Metal Engineering Co., Ltd

The pioneer manufacturer of heaters & sensors

| Place of Origin: | China |

| Brand Name: | GME |

| Certification: | CE |

| Minimum Order Quantity: | 50pcs |

|---|---|

| Packaging Details: | cartons, pallet |

| Delivery Time: | 7~10 working days |

| Payment Terms: | T/T, Western Union, MoneyGram, L/C |

| Supply Ability: | 100000 pcs per Month |

| Power Source: | Electric | Dimension: | Customized |

|---|---|---|---|

| Voltage: | 12-480V | Sheath Material: | Stainless Steel Or Nickel |

| Cross Section: | 2.2*4.2mm | Style: | Straight Or Coil |

| Lead Wire: | Copper, , Fiberglass Silicon | Coiling Scheme: | Tangential, Radial Exits, Axial |

| High Light: | electric resistance heater,coil heater with thermocouple |

||

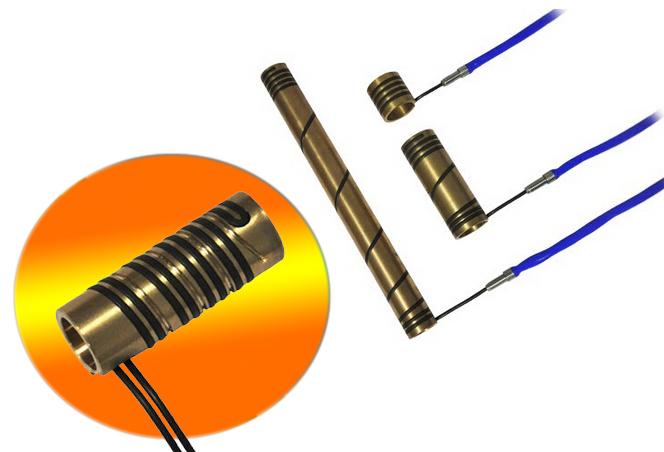

Industrial hot runner nozzles coil injection molding heater in brass

Description:

1) GME Hot runner heater’s production length in 200-3000mm is mainly used for hot runner mold or, as well as other precision heating system. Spring heating ring external using high quality Ni-Cr steel tube, the internal use of high purity magnesium oxide , high temperature resistance wire, and first-class manufacturing technology . The wire is after the annealed, with flexibility can be bent into an arc or circle heating. Its high working temperature, fast heating, uniform heating precision, long service life, can be automatically controlled area, high thermal conduction, while internal heating material damage, external can reuse.

2) GME manufactures high quality minitubular heaters that assure the best with respect to safety and performance. Minitubular heater owes it importance to his great versatility; the possibility to reach high working temperatures in small spaces allows to support the most difficulit needs. GME's minitubular heater can be manufactured with differents lengths, powers and sections, and are avaliable from stock also with thermocouple built-in (type J).

Specification:

Voltage: up to 250 V

High voltage flash test (cold): 800 V (AC)

Insulation resistance (cold): > 5 MΩ for 500 V (DC)

Leakage current (cold): < 0.5 mA for 253 V (AC)

Surface temperature: max. 750°C

Length : max. 3000 mm

length tolerance: ± 5%

Diameter tolerance:± 0.15 mm

Leads: PTFE insulation, heat resistant up to 260°C

Power tolerance (cold) Standard:±10%

On request: ± 5%

Sheath material: quality 1.4541

Power density: max. 15 W/cm²

Resistance per meter heated length: 20 to 1400Ω

Thermocouple: type J / K

Test Following to EN 60335/2/11 & EN 60204-1

| Round(DIA) | 3mm,3.3mm,3.5mm |

| Square | 3X3mm,3.3X3.3mm,3.5X3.5mm |

| Rectangular | 2X4mm,4.2X2.4mm,1.3X2.3mm,4.2X2.2mm |

Application:

1) Hot runner Injection moulds.

2) Hot Runner Nozzles & Bushings

3) Medical, analytical equipments

4) Packaging machineries

5) Other precision heating systems

Features:

1) A very wide contact surface results in exceptionally high levels of thermal conductivity towards the body that needs to be heated.

2) Optimal insulation results in very long life duration.

3) Heavy-duty construction results in very high resistance to mechanical shocks.

4) Operation temperature up to 700°C (1300°F).

5) Optional built-in thermocouple for high-resolution temperature measuring (J-type standard; K-type on request)

6) Unlimited range of possible shapes obtained from the straight heater.

Heaters can be incorporated into brass or aluminium castings.

Shipping: