Wuhan Global Metal Engineering Co., Ltd

The pioneer manufacturer of heaters & sensors

| Place of Origin: | China |

| Brand Name: | GME |

| Certification: | CE & ISO |

| Model Number: | 4.2 X 2.2mm |

| Minimum Order Quantity: | 10 pieces |

|---|---|

| Price: | negotiation |

| Packaging Details: | Export Carton Box |

| Delivery Time: | 7-15 working days |

| Payment Terms: | L/C, D/P, T/T, Western Union, Paypal |

| Supply Ability: | 20,000pcs per month |

| Product Name: | Coil And Cable Heater | Thermocouple: | Type J, K |

|---|---|---|---|

| Application: | Injection Mold Hot Runner | Material: | Stainless Steel 304, 316 |

| Moisture Proof: | IP 65 | Insulated Material: | Comressed MgO |

| Warranty: | 1 Year | Lead Wire Length: | 1000 Mm Or Customized |

| High Light: | electric resistance heater,coil heater with thermocouple |

||

4.2 X 2.2mm Hot Runner Spring Heaters With Stainless Steel Braided Protection Sleeve

1. Coil Heater Brief Introduction

Coil heaters are made of nickel chrome resistance wire placed inside chrome nickel steel tube filled with MgO powder and compacted for faster and efficient heat transfer. The heaters are annealed to acquire malleability for bending into any shape. Hot runner heaters with built in thermocouple are also available. Hot runner bushes are produced with hot runner heaters of different cross section with inner brass and outer stainless steel cover.It's high working temperature, fast heating, uniform heating precision, long service life, can be automatically controlled area, high thermal conduction, while internal heating material damage, external can be reuses.

2. Feature

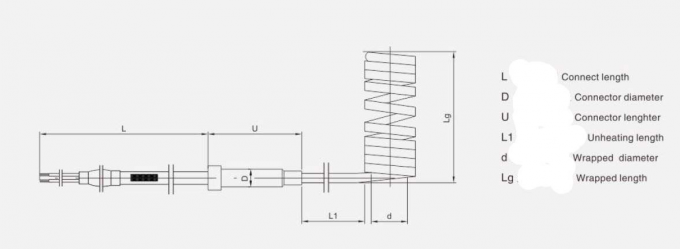

3. Coil Heater Parameter.

|

Spring coil heater (H series) |

3.0x3.0 |

Φ3.0 |

Φ4.0 |

Φ5.0 |

3.5x3.5 |

5.0x5.0 |

|

Voltage |

220V,230V,240V |

|||||

|

Power tolerance 115W-200W |

+/-10% |

|||||

|

Power tolerance 201W-2000W |

+5%-10% |

|||||

|

Out jacket length |

30mm~280mm |

|||||

|

Diameter of the inner sleeve/wrapped diameter |

10mm~42mm |

|||||

|

Unheating length |

45mm |

|||||

|

Max power density |

9W/cm² |

|||||

|

Heating Length tolerance |

+/-0.05mm |

|||||

|

Unheating length tolerance |

+/-2.5% |

|||||

|

Tolerance ID d ≤20mm |

Without inner sleeve:-0.15mm |

|||||

|

Tolerance ID d 20mm~30mm |

Without inner sleeve:-0.20mm |

|||||

|

Tolerance ID d ≥30mm |

Without inner sleeve:-0.25mm |

|||||

|

Tolerance cross section |

+/-0.15mm |

+/-0.20mm |

||||

|

Thermocouple |

K,J,E |

None |

||||

|

Material |

304,321,316 |

|||||

|

Maximum working temperature |

650℃ |

|||||

|

Die electrical strength |

800V |

1000V |

||||

4.Spring Coil Heater Application

This Heating Coil is widely applied for hot runner system, plastic industry, packaging machinery, medical

equipment, casting process,other electric heating industry, etc..